Background:A key retail client with over 100K SKUs, is losing sales because of stock outs in some categories & over stocking in others. Client wants to increase revenue by minimizing stocks outs & cut down over stocking costs.This is a complex supply chain problem which needs to account for both demand side improvements as well as supply side improvements. Client has international vendors who lead times go into months; hence there is need to house sufficient safety stocks to account for lead time & review time variability.

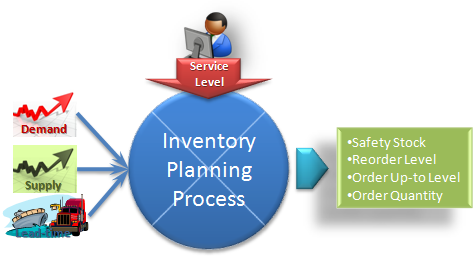

Approach:An automated SAS based forecasting & inventory planning model was built at a SKU- Market level to accurately determine the sales forecasts & then use the sales forecasts to determine the safety stocks, order up-to inventory levels& ordering quantity. The model would account for current inventory levels,vendor lead times, client review times, forecasted customer demand & then determine the ordering quantity on weekly basis.

Impact: Post introduction of Forecasting & Inventory Planning model on a particular category of products, client saw a significant reduction in lost sales due to stock outs & an increase in cost savings with the reduction in over stocks

Reduce stock out loses & cut down over stocking expenses